Proper maintenance of an industrial dryer is essential to extend its lifespan, ensure optimal performance, and minimize energy consumption. Just like household dryers, lint buildup is one of the main factors that can cause malfunctions and reduce equipment efficiency.

That’s why we’re sharing these 7 industrial dryer maintenance tips, based on the latest recommendations from our technical specialists.

The importance of cleaning industrial dryers

Lint is the silent enemy of any industrial dryer. Its accumulation can clog filters, ducts, and fans, directly affecting drying capacity, airflow, and energy usage.

Regular and proper cleaning not only prevents breakdowns but also helps the machine operate like it did on day one.

Lint Filter: Key to maintaining your industrial dryer

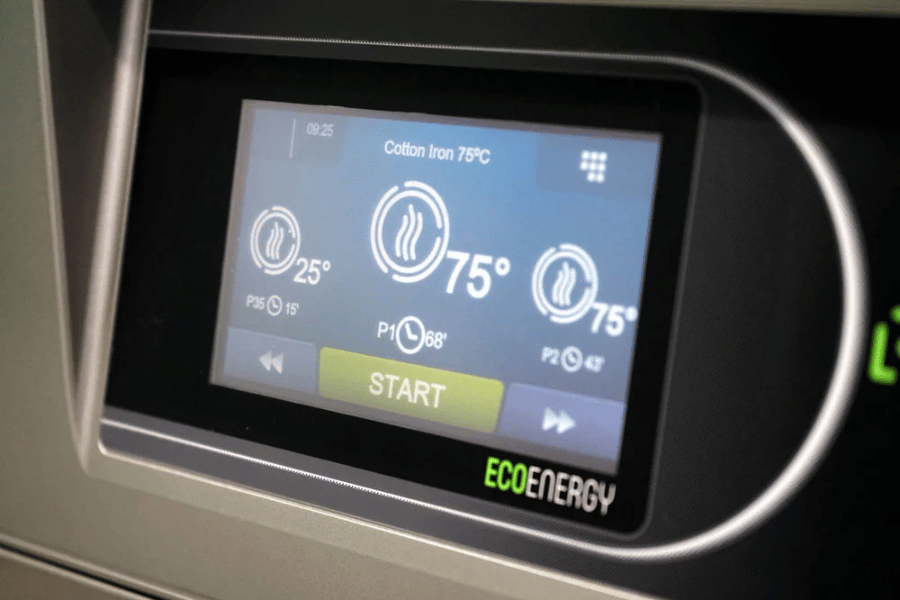

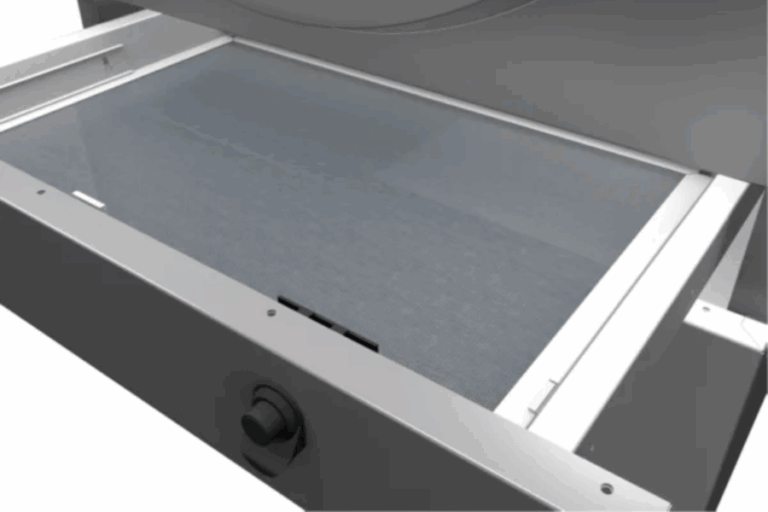

In all DOMUS industrial dryer models, accessing the lint filter is easy: just open the drawer located just below the loading door.

These filters are made from stainless steel mesh and designed to keep particles from reaching the exhaust fan.

Domus tip: Cleaning the filter after every cycle not only improves performance but also reduces heating consumption.

7 Maintenance tips for your industrial dryer

TIP 1

Clean the lint filter after every use.

This ensures efficient drying and prevents overheating.

TIP 2

Avoid using metal or stiff brushes.

These can damage the mesh or release dangerous metal fibers.

TIP 3

Use protective gloves when cleaning the filter by hand.

Operator safety is just as important as equipment safety.

TIP 4

Inspect the drum daily before starting a new cycle.

This helps prevent damage to both clothing and machinery from foreign objects.

TIP 5

Vacuum and deep clean once a month.

This monthly maintenance prevents internal lint and dirt buildup.

TIP 6

Never block the exhaust ducts or doors.

Good airflow prevents overheating and ensures even drying.

TIP 7

Keep the area around the dryer clean and free of flammable materials.

Avoid storing products like gasoline or solvents near the machine.

How often should you perform deeper maintenance?

In addition to daily and monthly maintenance, we recommend following the service routines every 200 and 2000 hours of operation, as specified in the user manual.

Also check out: our article on preventive maintenance for industrial washers and dryers in winter, with key tips for colder seasons.

Why is industrial dryer maintenance so important?

Poor maintenance doesn’t just shorten the equipment’s lifespan, it also increases drying times and energy usage. This directly leads to higher costs and lower productivity for your industrial laundry business.

Need technical support or more information?

If you’d like more information or a personalized quote to improve maintenance or renew your fleet of industrial dryers, get in touch with our sales team.

You can call us at (+34) 93 888 71 53, email us at domus@domuslaundry.com, or fill out the contact form on our website.